Optimise your plastic injection plant

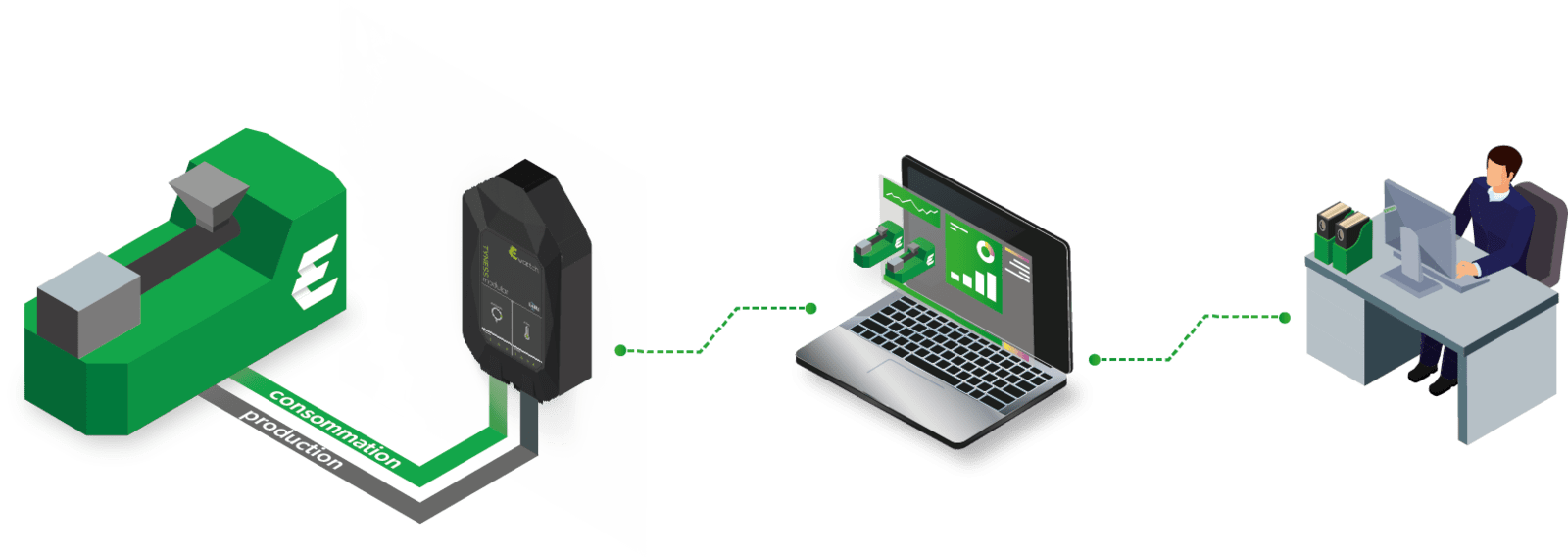

Digitise your production tools in just a few minutes

and optimise your plastic injection plant at all levels: production, maintenance, energy consumption…

Would you like to find out more? Feel free to contact our expert in plastics processes.

Simplicity at the service of Plastics Industry

Because simplicity is our priority, Ewattch Plastics offers you an affordable, Plug & Play and universal solution,

to boost your competitiveness.

A solution dedicated to Plastics Processes

Since 2016 and throughout France we have deployed a packaged solution including a connected wireless sensor TYNESS-ENERGY, and our software for the supervision and optimisation of the plants. This solution is the successful conclusion of several years of co-production and exchanges on the needs of our customers and the practices of the Plastic injection sector.

They trust us

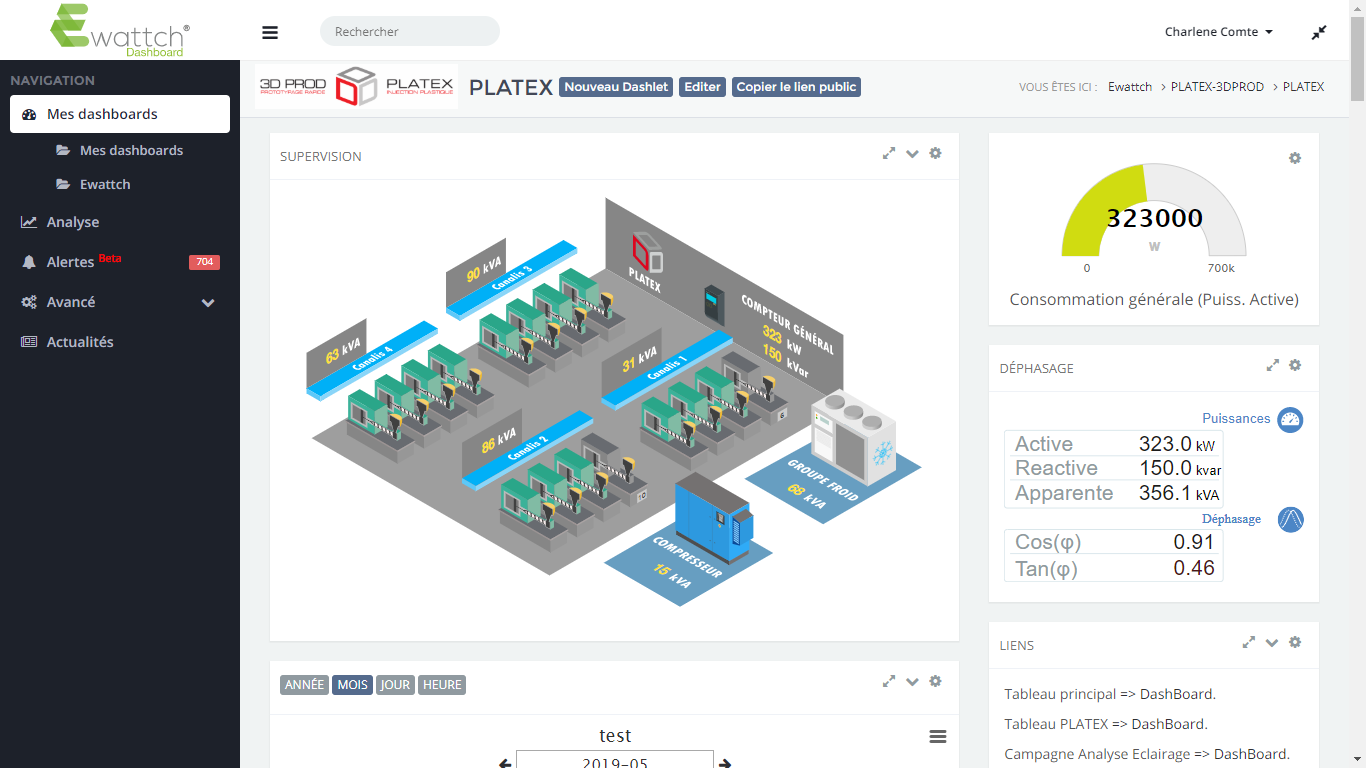

Installed in the Grand Est region since 1966, Platex is a plastics processes company specialised in plastic injection.

Our collaboration in a few figures :

PLATEX

“Thanks to the Ewattch tools, we record our electrical consumption and identify the energy-consuming workstations. The analysis of these readings has enabled us to reduce our electrical consumption by more than 25% in two years for an identical production level. Today, our presses are fitted with the TYNESS box and with supervision and color codes, we can visualise the status of the entire existing equipment in real time.“

Pierre-Alain REVERT

Continuous Improvement Manager, PLATEX